Take the Shock out of Baling with Impax

Take the Shock out of Baling with Impax

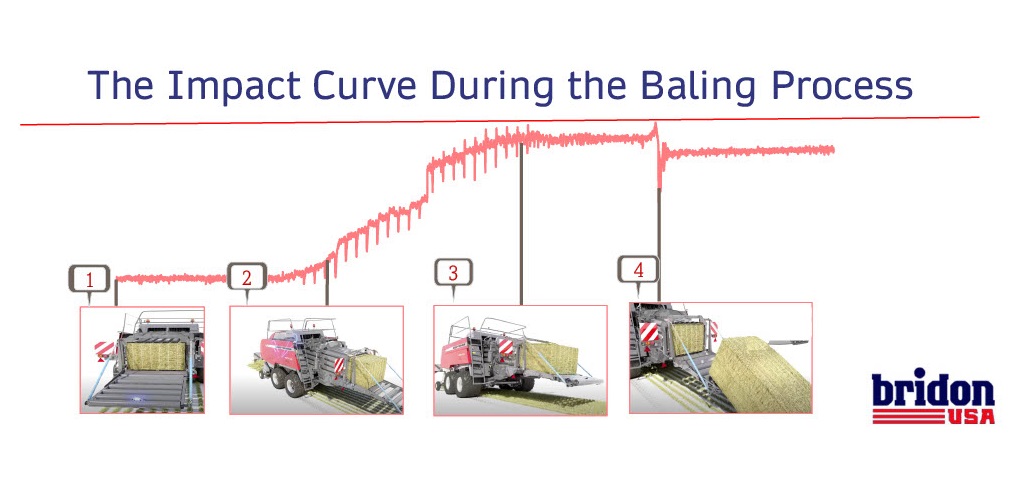

When choosing a twine, we often refer to the knot strength of our preferred product for the baling application, but how do we know which knot strength to choose? If we only looked at the knot strength needed to hold the bale together after the bale has been made and the associated handling and storage, we would not be considering the peak point of tension and repeated impacts that the twine experiences during the baling process. The twine on each bale experiences up to 20% higher peak tension as the bale is being ejected from the bale chute, compared to a static bale in the field or in storage. This peak tension, combined with the impact forces of the plunger requires the strength and energy absorbance of the twine to be much higher than simply holding a static bale together. In order to overcome these forces, we must either choose a conventional twine that’s overbuilt to withstand the peak tension, therefore using a twine with a thicker diameter, or we can consider an innovative solution from Bridon USA to combat the impact forces and peak tension with energy absorption – called Impax Technology. This cutting-edge technology allows us to produce a thinner, but more dynamic twine that improves efficiency in the field and reduces costly downtime that many conventional twine users experience. Take the hassle out of baling and produce more bales per hour, while allowing the baler to reach its maximum potential this season with Impax Technology.

For more IMPAX Technolgy information: https://www.bridon-usa.com/product/bridon-max-impax-technology-inside/

The Latest